Put some fresh 20W50 in and swapped out this ugly looking breather with one that matches better.

My 1970 Oldsmobile Cutlass S

- Thread starter Olds 307 and 403

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So I remember Mark mentioned the SBF main studs were a 1/2" longer than Olds replacements. He accidentally sent me 7/16" ARP head bolts. Not the end of the world, I have two 350's. I figured out the the 221 through 302 has the 7/16" mains like 1-4 on the SBO. The 351W has 1/2" mains. I paid less with shipping through Amazon then Summit's price before shipping. I plan on dropping off the block in August at the machine shop, studs should be here mid July. I also did some cosmetic things to the 70S. I removed one button in the driver's side seat. It would always catch and pull out and wear the top out. Ivory silicone filled the hole and matched the pearl interior near perfect, looks a lot better. I also reguled one rear window moulding. I plan on washing it and taking it to the neighbouring city today.

So I washed the 70S, looked pretty good for a horrible paint job on a rotted car. The good, no overheating, only a tiny amount of oil used and the fuel gauge hardly moved. I will figure out the mileage this week, betting mid 20's. The bad, crappy oil pressure, no doubt from the bent rod, less than stellar performance, really shitty idle along with the lifter clatter and a squeak, maybe the alternator belt yet again, 5th time is the charm. I was just about home and a R/T Challenger passed me. I was delayed in my reaction but I had no chance to repass him, way out classed in power. It reinforces I need the 9.6 to 1 roller cam Olds 424, manual valve body 4L80E and at least 3.42 gears. I also hate the stock calibration 2004R with the stock 3000 rpm governor. I have the TV cable in the max position, full TV pull and there is no slippage occuring. I wonder if the converter is dying, it engages instantly in gear but needs a little throttle to get moving. It is a mild stall, flashes at 2300 or did before. The block is going to the machine shop soon, I need to spend some dollars and get the drive train how I want it.

Mileage was only 17 mpg first trip, similar the second as well I would bet. If I can't have mileage, I need blistering power😎. Well, it still has a steady squeak at speed, just loud enough to be annoying, goes away pretty much below 30 mph. Sounds like it is on the driver's side. I checked both drums for temperature, felt the same. I repacked the bearings when I did the front brakes. I may try soap on the belts to help eliminate them. I will Jack up the front end and spin by the wheels by hand, need to check brake adjustment anyways, maybe a tiny rock in the brakes but usually that is amplified hitting the brakes, no difference. Maybe the speedometer? I have had that happen in other cars, a less steady sound than this. My Wife said it sounded like I had a little bird in car.

Rocketman269V

Member

No coming from the front, much quieter now. I tightened the alternator belt yet again that may be the culprit.

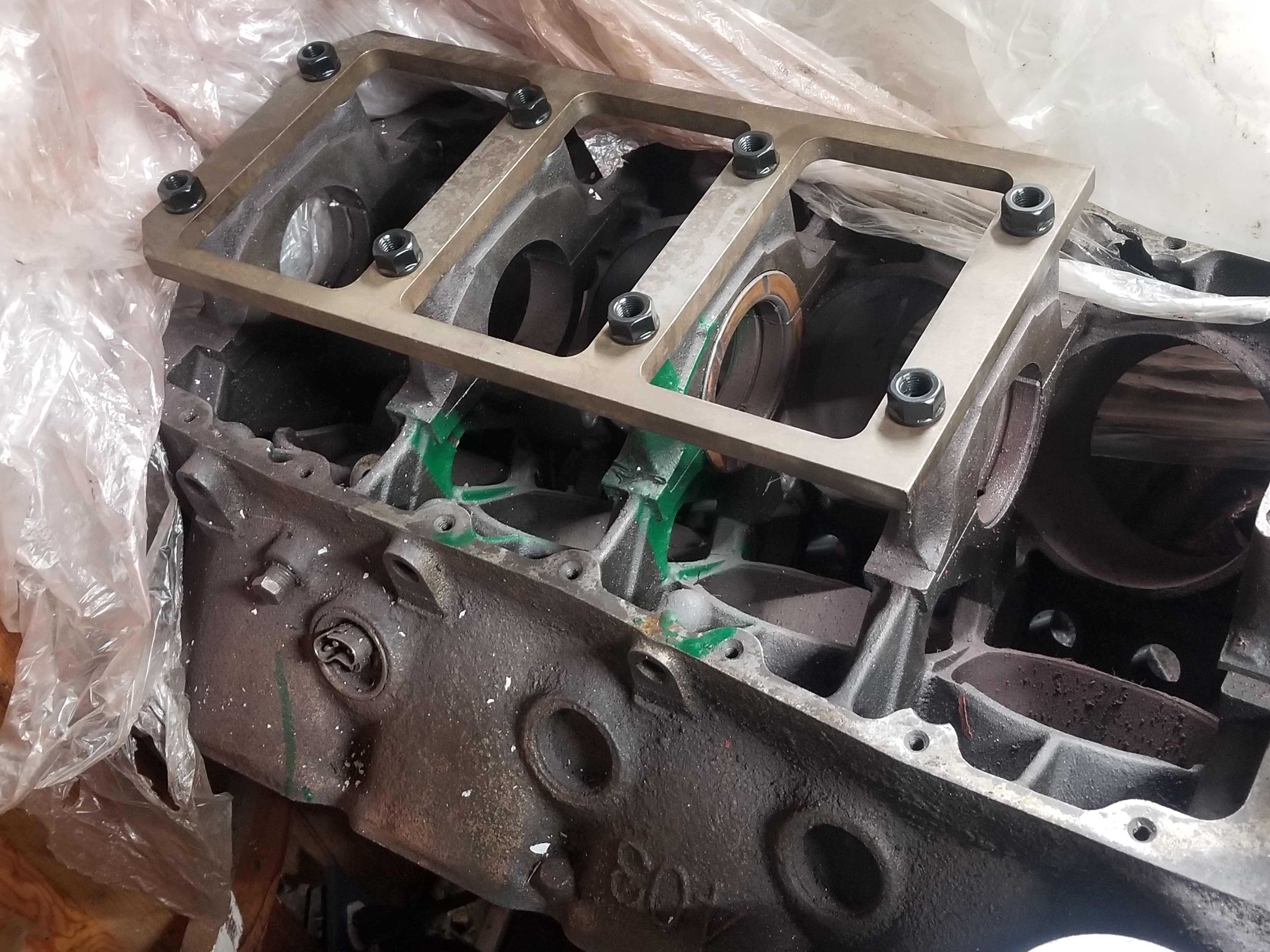

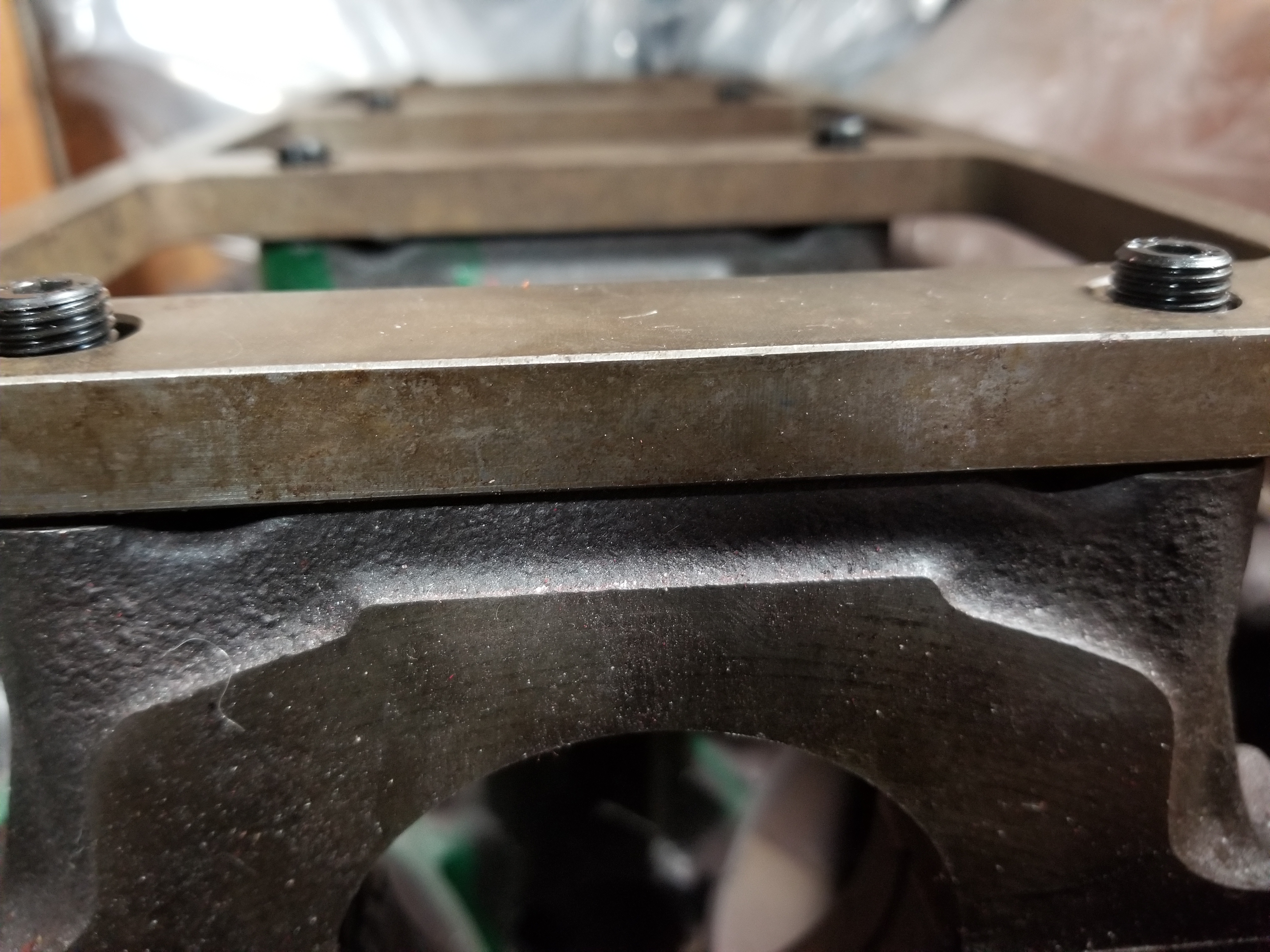

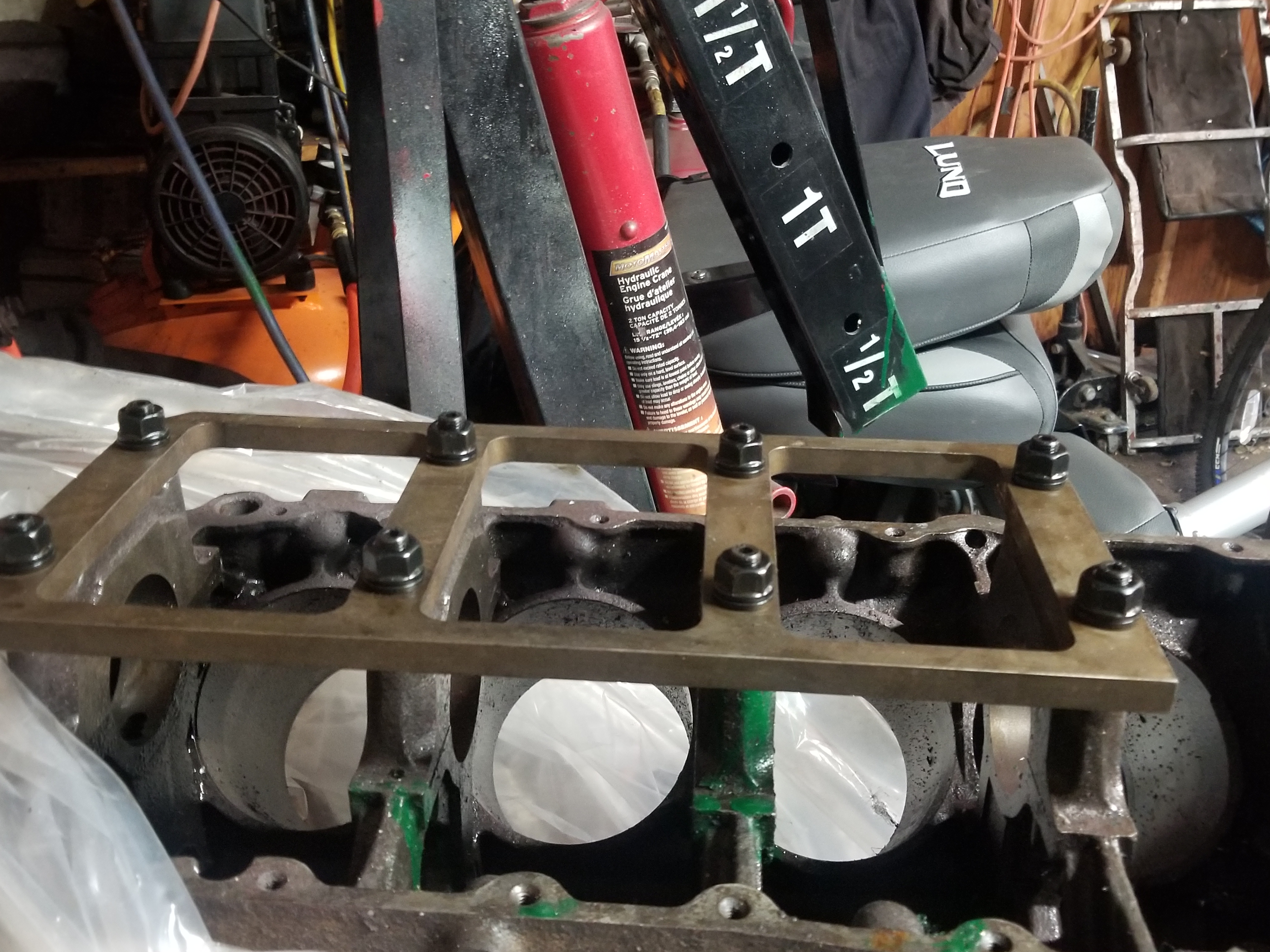

Well, I adjusted all 4 brakes tighter to the drums. That smartened up the pedal pretty good, brakes start applying nearly right away compared to half way down. There some play in the lower shock bushings and upper control arm bushings on the rear end. Both have a small gap on the inside of the bushings maybe enough to move everything?Should probably get adjustable uppers and new rear shocks. I also recieved my main studs. Pretty sure I needed the 1/2" longer studs, thought basic 302 studs would be long enough. Did Olds and Ford work together on design their SB V8's, rocker arms and main studs interchange. They are the perfect length as you can see by the pictures. Maybe I will keep them for another build or mill the caps. The whole point of the longer studs was to not mill the caps. I may just get the 1/2" longer 302 studs and use these with my 350 block, I already have 7/16" ARP head bolts, nearly fresh 2.05"/1.56" #6 heads and a 330 crank for it.

The other I did was grease the front and look at the oil leaks. The Edelbrock M/T copy aluminum valve covers look pretty but have given repeated grief for leaks even with the now discontinued Felpro permadry valve covers and Rocket Racing rubber valve cover gaskets with the rigid carrier. This time I used the used the Right Stuff on the head side putting the most worn out side on the head side with the Permadry gaskets. Still the same seeping/small drips on both sides, clearly coming between the gasket and cover. The trans pan looks really good, a relief, the last Hughes deep pan. The selector shaft seal is leaking, last 3 2004R'S have done this. Also the speedometer gear, another common one and the weep hole at yoke, that one is confusing. I am thinking about building the 2004R with all the good parts. With a 9.5 to 1 roller cam 424, 2004R and 3.90 gears, only the hottest new cars would lay it out. By the time I add up a $500 minimum used 4L80E along with a manual speedo conversion, controller and a good converter is easily at 2 grand with a used questionable trans and less than ideal gearing. The 2004R with the best gearing of any 4 spd OD trans just needs the $400 DR Dan converter and about a 2 grand CK kit along with whatever trans tools I need and a lot of time, careful measurements and assembly. I could maybe try a used TH350 with a Transgo shift kit dual feeding to give it any chance. I saw how long a TH350 lasted with a smogger 454 swap in a Camaro, not long. The next one with the shift kit lasted pretty well under heavy abuse. It would still need something like the Jegs affordable 2300-2700 stall converter. The TH400 is an option used but the driveshaft difference is a killer. Not like these cars are littering the junk yards anymore and finding a BBO car is even harder. I do have a spare 80's big car drive shaft that could be shortened but a 32 spline yoke and conversion U joints, making it hundreds of dollars. Another and the biggest PIA part of the 4L80E swaps well. I can get this motor done this year, the trans is more difficult. The Type O 3.90 gears and a good posi is also another $1000 bill with me doing it. A high performance motor swap is easy, when big torque is made, the rest of the car becomes a problem.

So 302 main studs fit an Olds 260 through 403, 1 through 4. I am not too worried about 5 being 1/2"

bolts, no doubt similar in strength to the ARP 1 through 4, 7/16" studs. I have actually cracked a cap going to 130 ft/lbs but not broke a bolt, that torque wrench read 10 ft/lbs high, found that out after the fact and the spec was 110, not 120. The longer 302 studs for a girdle arrived, here are the results. Also should I blast off that paint that dripped on the block before machining? I already brushed on paint stripper.

bolts, no doubt similar in strength to the ARP 1 through 4, 7/16" studs. I have actually cracked a cap going to 130 ft/lbs but not broke a bolt, that torque wrench read 10 ft/lbs high, found that out after the fact and the spec was 110, not 120. The longer 302 studs for a girdle arrived, here are the results. Also should I blast off that paint that dripped on the block before machining? I already brushed on paint stripper.

I will pressure wash the block and clean out all the passages with brushes after machining. This shop has done Olds before. My coworker had his 455 done by them from a 72 Delta 88. It had low oil pressure so he sent it there. It ran hot in his second gen Camaro but no more oil pressure issues.

So my plans are to do at least one, if not two cosmetic things to this car in the next year. I am going to switch from my beaten S grills to 442 style grills. https://www.early-birds.ca/part_413_414_423-321034.htmlThey are cheaper and will change the look somewhat. The other is a new windshield, it is way cracked and stone chipped. I still plan on sending the 403 short block to the machine shop towards the end of the winter. But I plan on getting this 350 running better. I am pretty sure a lobe is dying on the 214/214 cam and one connecting rod is bent and the flimsy grey iron crank has a wasted rod journal. This motor had 150 psi in 6 of the 8 cylinders, 125 in 8 AND 115 in the bent rod 7. So I will be putting a parts wanted ad in the sites I visit for one good condition, used 73 to 80 14cc piston and connecting rod. I will get new standard Moly rings and hone the cylinders. I also have a spare 330 forged crank and flex plate that was balanced for Speedpro 18cc dish forged pistons with stock rods. I will need .010 rod and .020 main bearings. I will probably Copper coat and reuse the .028 head gaskets if possible. The current 62 to 64cc big intake valve rebuilt 6 heads with few miles on them, I plan on polishing to 70cc to run on the 403 stroker. I plan on polishing my 55cc, filled, ported with W31 valves 6 heads to a polished 60cc. this will put me at 9.25 to 1. If the cam is failing, probably is, I have a good 204/214 cam on the shelf. I have two timing sets to choose from, the floppy Cloyes street 3 way double roller and a good used stock replacement off the 260. I will degree it and see where the stock replacement set puts it. I am planning on getting a set of the Chinese stainless headers, which will hang low but I have a ton of ground clearance with car. The $177 Canadian dollars set on Amazon sold out with free shipping sold out, most places are. The best deal, I found in stock was $70 more. I am also planning on bungs in the collectors to run a wideband. Then 2.5 pipe but undecided on mufflers. I like Aerochambers but they are loud. I may try cheap stainless, straight through mufflers. I can add glass packs as resonators and also have 3 rolls of 3M sound and heat barrier to throw under the carpet. A huge improvement over the current cast 260 manifolds and 1 3/4 dual exhaust with glass packs. I am finally getting a 750 Street Demon, TV bracket and the 625 cfm tuning kit, it will match this motor better. The 2004R trans I already have a deep pan and a 2350 stall converter. I plan on buying the CK reman 10 vane pump and hardened stator. I will also get his shift kit and servo and maybe the wide band as it is the next recommended upgrade. The other big key is the 3.90 gears for the Type O rear. I think there is a member on CO willing to sell a brand new set for less money. I also need to decide if a spacer or the expensive converted 8.8 ferd posi since I have the 2.78 ratio. I will probably get better mileage, 17 mpg Imperial running 1350 to 1450 rpm is not great, it will be 1900 to 2000 rpm, I will gain if anything, not lugging so much. I did some measuring today to see if it is the rear end or body that is causing the tires to sit uneven in the wheel wells. It seems the whole body, front and back is shifted to the driver's side.

So I've had trouble finding the one piston and rod I need. I am seriously considering building the current 350 with better pistons and rods. The block should hone to 4.065" oversize. I have nearly fresh 2.07"/1.56" heads with the bowls opened with a cutter. They are 62 to 64cc. I would even the chambers to 64cc, add new positive seals and roller cam springs. I would also blend in the bowl hog cuts into the ports. I have slightly used roller lifters, longer main studs and a 1/2" 4 main Halo. I also have a 330 forged steel crank that is cut .020" mains and .010" rods. It was balanced for the no longer available 18cc dish forged Speedpro pistons and stock rods. So they would have to remove weight to balance the crank. Would no doubt be cheaper than adding expensive Mallory metal. I also have new cam bearings. Basically, I would need a new Cloyes billet roller timing set, roller cam to my spec, Mahle 10cc dish 1mm ring pack pistons, new Scat or Molnar direct replacement connecting rods, rings, bearings and basic gaskets, already have some. I would also go with a BBO stock replacement pan. A deep mid sump and a rear baffle vs the stock SBO pan. I would only need the cylinders honed, cam bearings installed, cleaned up deck and a line hone along with balancing for machine work. Cutlassefi got nearly 420 HP and 400+ FT LBS of TQ with a flat tappet cam and similar heads. I will probably buy the Stainless Chinese full length headers to get it completed quicker. I would probably move the new A body aluminum/plastic rad, serpentine belt set up and electric fans from the 88 to the 70S. Of course, the 2004R will still need upgrades like the Billet forward drum, wide band and CK shift kit at minimum.

Another part I have is ARP 7/16" Olds 350 head bolts. Cutlassefi accidentally sent me them instead of the longer ARP main studs for the Halo. I am going to pull the heads, intake, the rest of the top end and accessories off the 350 in the next few weeks too access the cylinder conditions. I am doing this so I can work on the heads and not remove the hood to pull the motor. Man, the cool, bulging "S" hood, seriously weighs about 200 awkward pounds. Two of us in my little shop found it a huge challenge to take on and off. If it wasn't for the hood tooth, the motor would pull with removing anything. The 88 steel hood is a lightweight feather in comparison. I could slap this 350 together but 250 hp doesn't appeal to me. You know, barely 9 to 1, 204/214 cam and stock cast pistons with soft stock rods. With the Mahle pistons and Molnar rods with ARP 2000 rod bolts, ARP main studs with a 1/2" Halo, 7500 rpm should be no issue. Cutlassefi's 417 hp/433 tq 350 has a fair amount of bowl work and filled crossovers. I won't fill the crossover's but I will blend the bowl cuts into the roof, tear drop the guide bosses and remove the air bumps on the exhaust side. I would think a roller cam will allow better vacuum and manners with a similar duration along with more lift. I do have 1.6" Comp roller tip and 1.72" Scorpion SBF full roller rocker arms, 5/16" to 3/8" conversion studs and guide plates. Since the roller cam will be a custom, Mark can put the lift where he thinks it should be for iron heads. I am measuring the body today, I need to see if just the rear is cockeyed to one side or if the whole car is.

I did some more measuring. I tried measuring from the frame to the tire, could not get an accurate measurement on the front. So I went from the hole in the frame to the trim screw, within a 1/4 on the front. So much for the whole body put to one side from the factory. Now the back is a different story. The back I stuck the lip of the measuring tape through the hole in the frame, pulled it tight and measured to the outside of the fender near a trim screw, same on both sides. I got 4.5" difference! Yes, bondo and smutz in the hole could throw off the measurement some. It definitely noticeable and I didn't see any obvious frame twists but I will obviously be doing much more investigating. If it was smacked in the rear end, how comes it still handles and drives very nice? It can take corners way better than my 88 Cutlass. On a slalom course, the 4 wheel drum brakes would be the biggest challenge.

Rocketman269V

Member

Get a measurement from the rear of the frame, near the bumper brackets, to the lip at the bottom of the quarter panel. Also check between the frame and the pinch weld at the bottom of the rocker panel directly in front of the rear tires. Wheel well outer lips could be off for any number of reasons, but the pinch weld is what body shops use.

Yeah, only off a 1/2" at both places. It has to be an issue with the wheel tub as well. I may run a spacer, just on the driver's side.

I measured at the tires to the the edge of the outer fender lip. From what I measure, the passenger tire is 1" further out on the passenger side. So it is probably out a good 1/2" on the frame/body and probably the other half is the upper control arms. So maybe a 3/4" spacer on the driver's side should work, 1" will probably make trimming the wheel well trim ring, like on the passenger side.

So I put on my 3/4" spacer to test fit on the driver's side. It will make the wheels even in the wheel wells. So the studs are 3/4" and about 1 thread so I will probably just grind that one thread if there is interference. I have a 7/16" x 20 Tap and Die. I have Gorilla open end 7/16"x20 lug nuts. Of course they are twice as tall as the 12×1.50MM nuts that came with the spacers. Either grind time or try to find the factory lug nuts. No factory style nuts in town. I bought McGuard 12x1.50" lug nuts that look the same as the 7/16"×20 McGuard nuts on the rest of the wheels since the spacer has Metric studs.

Attachments

Ground the studs and used a Die on the threads. Found 7 of the stock lug nuts, the perfect height, probably 1/4" of stud past the nut and they are basically even with the spacer. I put Blue Loctite and torqued the spacer to 110 ft/lbs. I ground the lip slightly on the inner wheel well, just to be certain. The uneven wheel spacing from side to side looks like shit. It is much closer now.

Attachments

This arrived today.

I figure a working tach and an AEM wideband are two necessities before the new motor goes in. Hopefully an Autometer tach will work with the Mallory 6AL.

I figure a working tach and an AEM wideband are two necessities before the new motor goes in. Hopefully an Autometer tach will work with the Mallory 6AL.

Similar threads

- Replies

- 1

- Views

- 3K

- Replies

- 0

- Views

- 3K