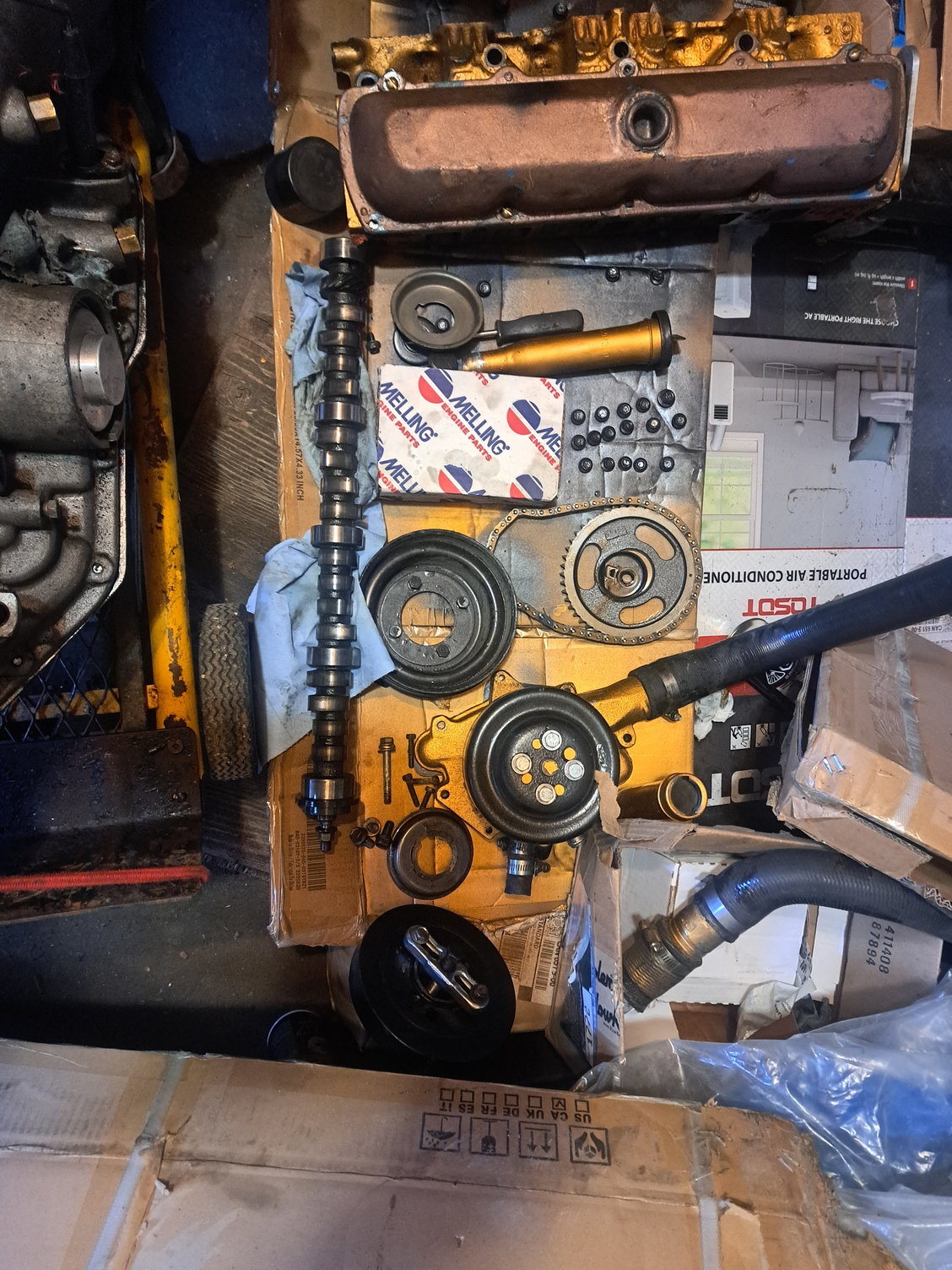

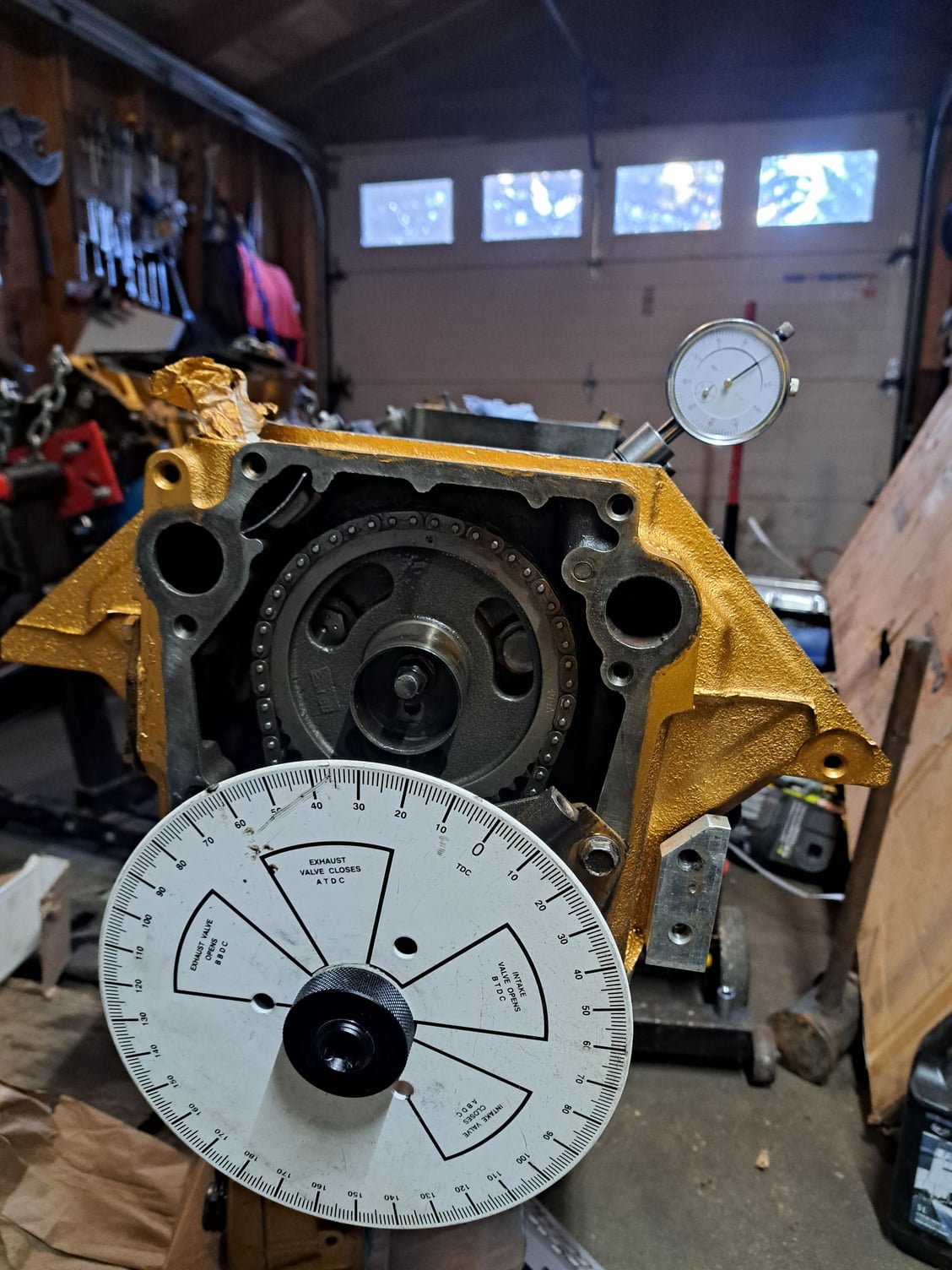

Got the dehumidifier running in the garage, was 70 percent, now down below 50 percent. It was dry all Summer, now that motor is in the garage, we have been getting rain. The Melling high volume oil pump is torqued to 35 ft/lbs. I tightened the Canton pick up and gasket with a long 1/2" wrench. I can't get a torque wrench on one side, so just reasonably tight. I cleaned then torqued the oil filter adapter with a steel core gasket with a very small amount of Right Stuff One Minute on both sides to 35 ft pounds with some nice stainless 3/8" × 1" fastners I had lying around. I put on the nitrile coated, rigid core Felpro OS30471C pan gaskets, used the Right Stuff One Minute to glue it to the block. I torqued the Canton 6 qt pan in place to factory specs as it is very slightly warped. I am painting the factory flanged bolts VHT Black Metallic high temp once it sits for a few hours, this afternoon. I also cleaned and painted my best spare timing cover VHT Gold Metallic high temp paint. I will put new gaskets and front seal and paint top rear of the timing cover. Keeping the 358 sealed in plastic in between work on it. It also looks like a pilot bushing is installed, I was planning on a TKX in the next couple of years.