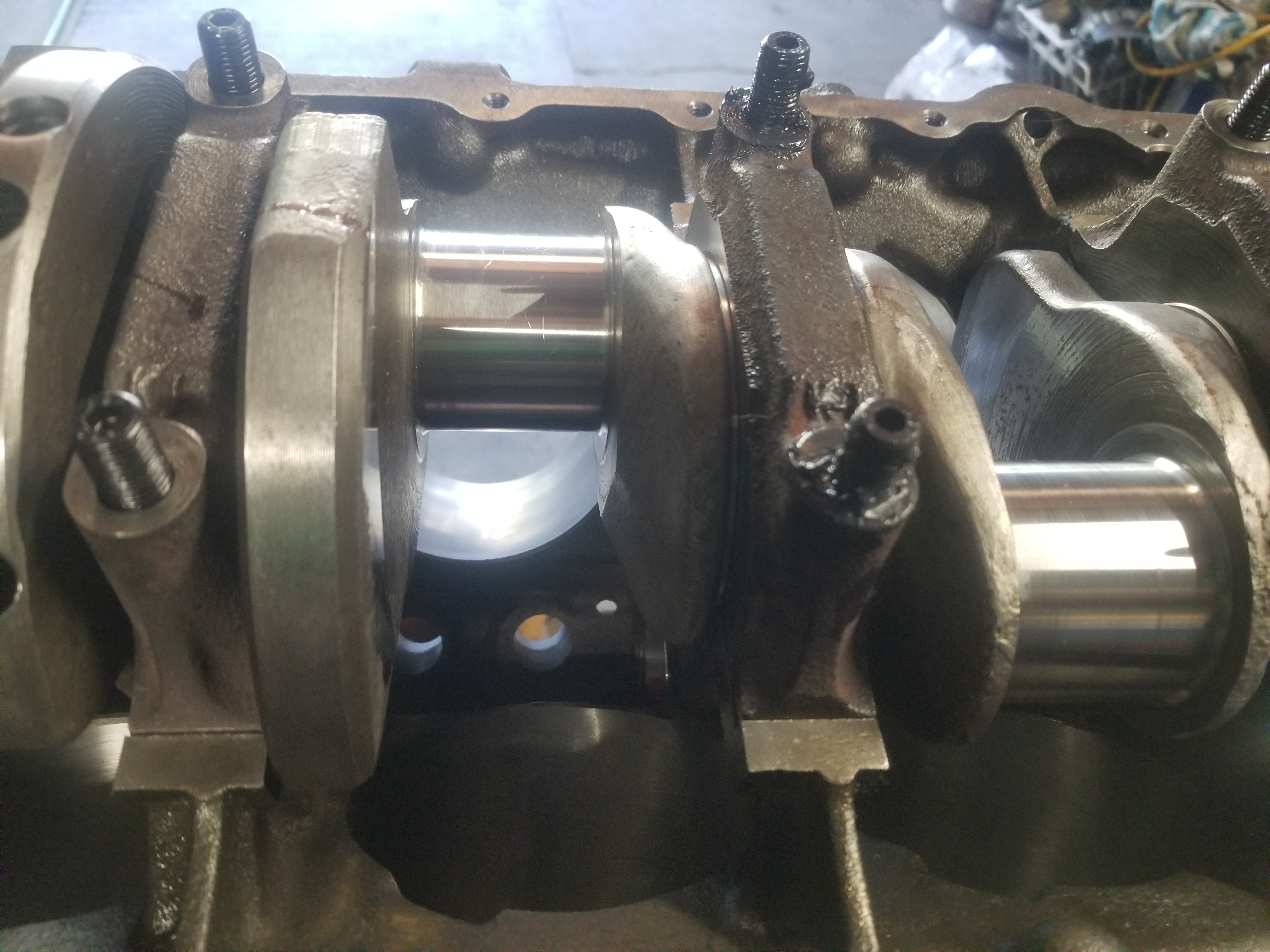

Ok so I lubed the tops of the bearing caps the same way with Permatex Ultraslick. I tapped the caps all into place. I trimmed off the ears on the AMC 258 main seal, lubed with ATF installed with the groove towards the motor and two small dabs of The Right Stuff. I set the thrust bearing by tightening down the center main bolts with a ratchet then backing off to finger tight. I then spun by the crank by hand tapping back, then foward with my plastic 2 pound dead blow hammer. I then torqued #3 to 80 ft/lbs with ARP lube on both sides of the washer and threads, along with all the mains. I then torqued the rest of the mains to ARP torque specs. The crank spins very easily by hand. I measured .008" for thrust clearance. .007" is loose and .009" is tight.

Ok so I lubed the tops of the bearing caps the same way with Permatex Ultraslick. I tapped the caps all into place. I trimmed off the ears on the AMC 258 main seal, lubed with ATF installed with the groove towards the motor and two small dabs of The Right Stuff. I set the thrust bearing by tightening down the center main bolts with a ratchet then backing off to finger tight. I then spun by the crank by hand tapping back, then foward with my plastic 2 pound dead blow hammer. I then torqued #3 to 80 ft/lbs with ARP lube on both sides of the washer and threads, along with all the mains. I then torqued the rest of the mains to ARP torque specs. The crank spins very easily by hand. I measured .008" for thrust clearance. .007" is loose and .009" is tight.

Ok so I lubed the tops of the bearing caps the same way with Permatex Ultraslick. I tapped the caps all into place. I trimmed off the ears on the AMC 258 main seal, lubed with ATF installed with the groove towards the motor and two small dabs of The Right Stuff. I set the thrust bearing by tightening down the center main bolts with a ratchet then backing off to finger tight. I then spun by the crank by hand tapping back, then foward with my plastic 2 pound dead blow hammer. I then torqued #3 to 80 ft/lbs with ARP lube on both sides of the washer and threads, along with all the mains. I then torqued the rest of the mains to ARP torque specs. The crank spins very easily by hand. I measured .008" for thrust clearance. .007" is loose and .009" is tight.