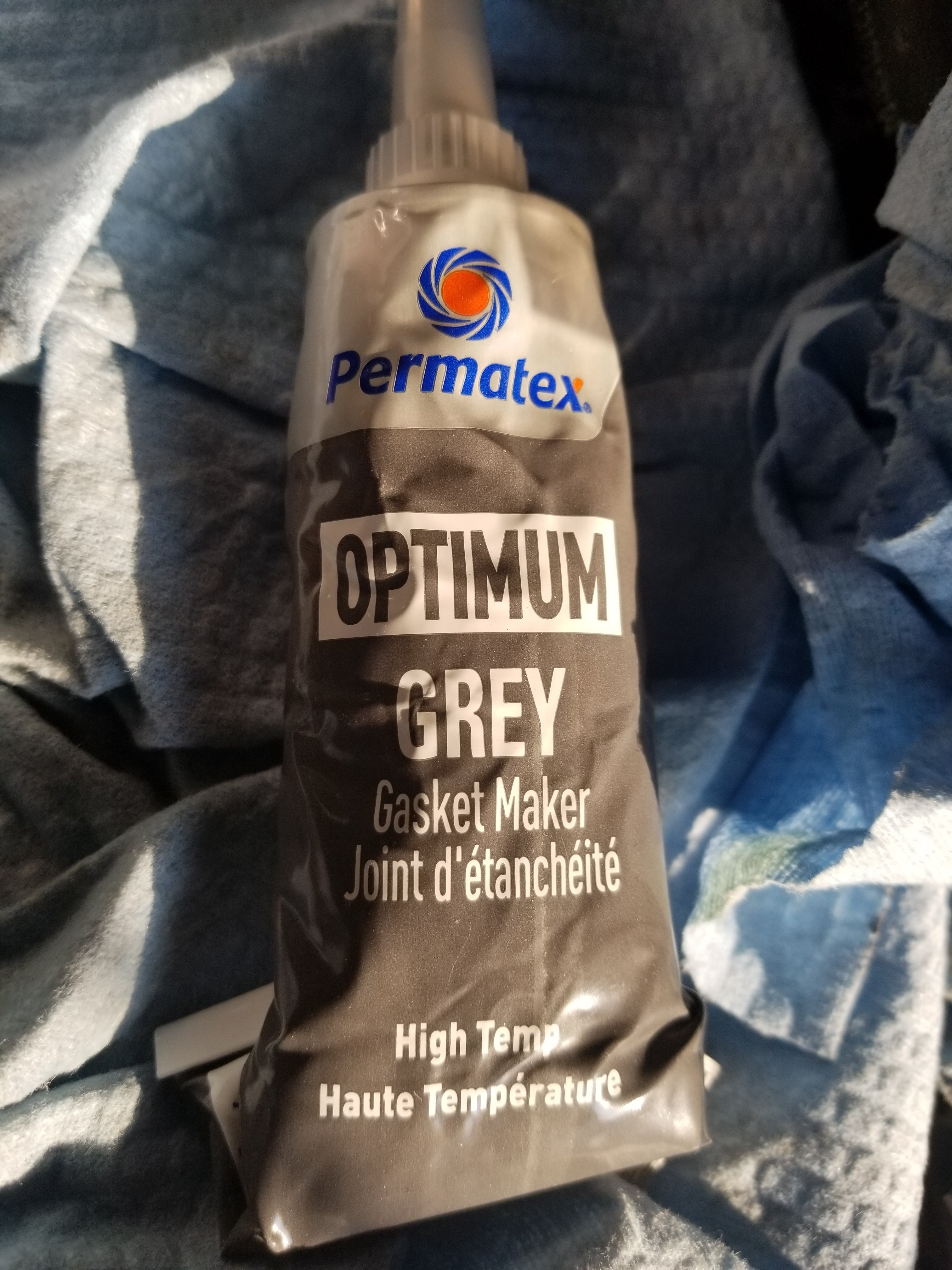

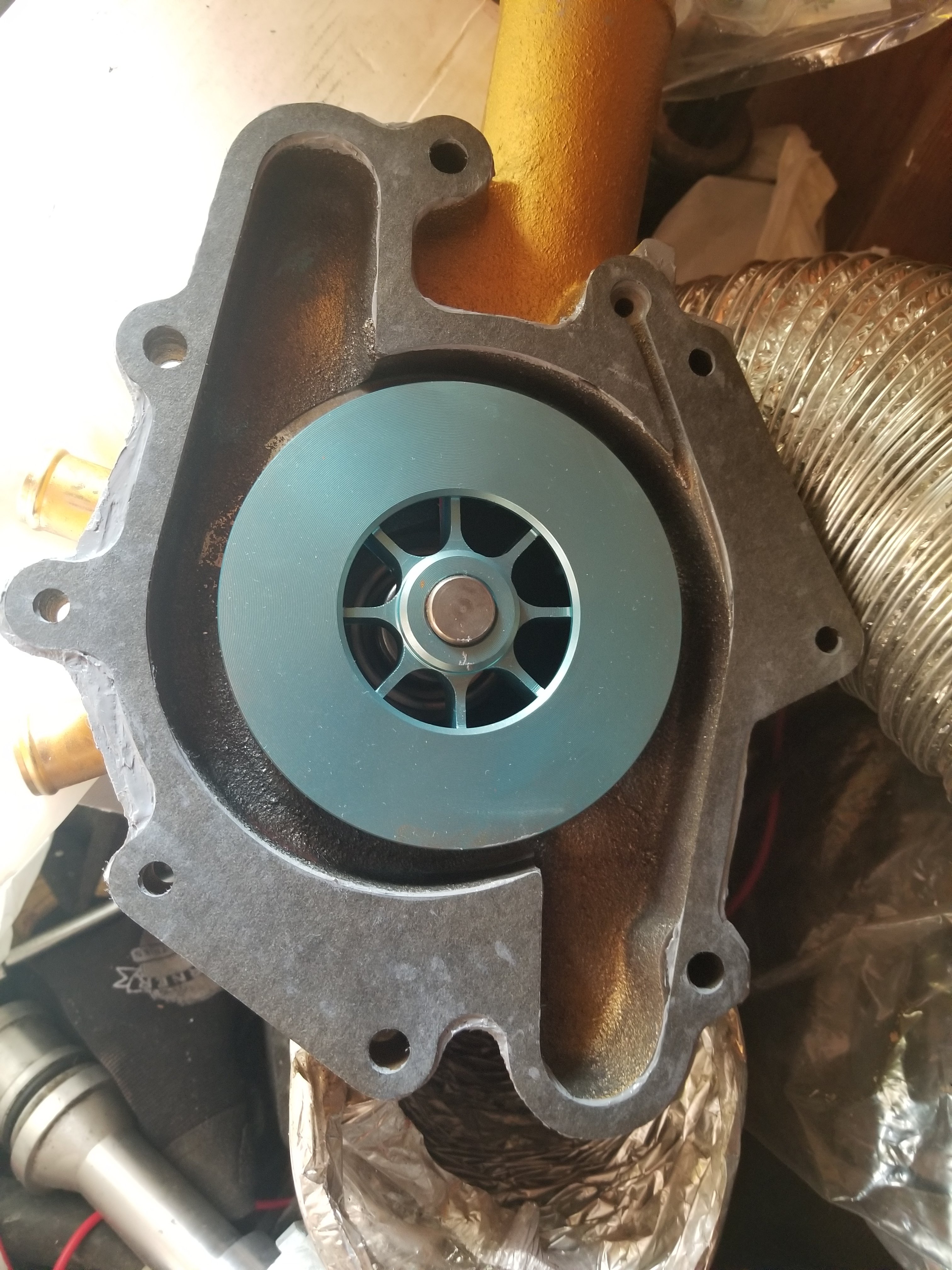

Decided to glue on this gasket to the reverse rotation Flowkooler water pump. Since this gasket does not exist outside of buying this pump, gluing to the pump is much more ideal than the cover. Of course, I used the best RTV on the market.

Oldsmobile 374 stroker build

- Thread starter Olds 307 and 403

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JAMCAR223

Member

I installed my gasket the same way, but used Permatex Ultra Black.

Since I own (4) of these reverse rotation pumps, I also tried to buy a couple gaskets to keep as spares. Nope! A/C Delco has discontinued them, and Fel-Pro has also discontinued them. I have a couple gaskets that were in bad shape that I will use as templates to make my own, using universal "square sheet" gasket making material.

Since I own (4) of these reverse rotation pumps, I also tried to buy a couple gaskets to keep as spares. Nope! A/C Delco has discontinued them, and Fel-Pro has also discontinued them. I have a couple gaskets that were in bad shape that I will use as templates to make my own, using universal "square sheet" gasket making material.

Not the worst idea, considering that myself. My first pump from RA beat and destroyed the gasket during shipping, was not impressed. Make me a spare and I will buy it from you.I installed my gasket the same way, but used Permatex Ultra Black.

Since I own (4) of these reverse rotation pumps, I also tried to buy a couple gaskets to keep as spares. Nope! A/C Delco has discontinued them, and Fel-Pro has also discontinued them. I have a couple gaskets that were in bad shape that I will use as templates to make my own, using universal "square sheet" gasket making material.

JAMCAR223

Member

I'll make a couple one day soon when I'm bored. You don't have to buy it... I'll send it to my Oldsmobile brother for free.

Talked to machine shop today, the crank is ground! It is .030"/.030", they need rings and rod bearings to internally balance. I told them to get me rod bearings to speed it up, nope. They called direct to manufacturer's, Clevite, Federal Mogul and King, no one had any in stock. Sent Mark a message with the rest of the parts needed, hopefully they are available.

FYI to us SBO guys, Mark talked to Clevite and King both had .030" rod bearings in stock. The had zero .030" main bearings in stock and don't plan on making anymore. The Federal Mogul Bi metal bearing is the only option in that oversize. Summit has .040" as special order through King on rod and main bearings but that could be a long wait, probably the same for .030" mains.

I decided since I want to strip the Duplicolor garbage paint off the serpentine accessories and off my heads, blasting without a cabinet is brutal. I bought this at $70 off.

Also shipping is free due to Pandemic, so $150ish with a 52 bag of crushed glass shipped to my door. I already have this in yellow, which I will set up to feed this bad boy.

Also shipping is free due to Pandemic, so $150ish with a 52 bag of crushed glass shipped to my door. I already have this in yellow, which I will set up to feed this bad boy.

I talked to Mark, going off the spec for a 8171PT head gasket on the Summit Racing site of .039". I assumed that would leave me .036" piston to head, borderline but pr. He mentioned. 042" was the actual spec. I happen to have a used 8171PT hanging on a hook, it read .042" like he said, imagine that. That should put me at .039" piston to head, about perfect. I am going to polish the iron #6 chambers to 68cc so it will be apples to apples when I swap eventually to the Edelbrock aluminum. That will put me right at 9.5 to 1, should allow a nice timing curve on 91. The only variable will be the new 1.65 ratio(.541" lift) from Mark to 1 vs 1.6 ratio roller tip rocker arms(.525" lift), I also have 1.72 ratio(.564"), I may run but they need checking in the push rod cup area .I don't want anymore delays from this machine shop as the iron heads need .100" milled off the rocker pads to properly run the new rockers. I am probably selling my Performer intake as clearancing may be needed for the roller lifters and limits this combos. Not worth it to run the hot air choke.

I have a little more faith restored in my machine shop. I contacted them about checking the big end dimensions. He said, anytime the small end is checked or sized in my case, they automatically check the big end dimensions. So once the bearings arrive from Mark, balancing then assembly can happen!

More parts, almost all of them now. Mark has had issues with the Melling High Volume oil pumps, he contacted them about their gear feel issue, so waiting on that. My Daughter is going to Yorkton on Monday, getting her to drop off a ring set and a set of .030" rod bearings so the internal balancing can be completed. The look and feel of the US made Cloyes billet timing and my Daughter's Boyfriend was super impressed by how thin the ring set was. I told him Mahle's propriety material makes the 1mm/1mm/2mm ring pack possible. He noticed the laser etching on the ring.. He figured they would wear out quicker, I said actually the opposite. The ultra thin rings will last way longer without wearing like the thick 5/64" ring packs. It will also help seal with Mahle pistons needing half the clearance of the old Speedpro forged piston, .0025" needed. Getting closer, once the crank is back from balancing, already ground, assembly will begin. I will make sure my Daughter brings back my other parts so I can file fit the rings. The Cloyes US Billet timing set is so much nicer than any of the cheaper double sets I have used.

So the saga continues, the machine shop called and gave me the number of the balancing shop. He said, they could not internally balance my crankshaft. I called the guy, he said they didn't have the capability to add Mallory weights, WYF? Really, this is the shop you sent my crank to for internal balancing! I told him, weigh my pistons and rods, they are about 600 grams each. This 330 crank was supposedly balanced with heavy 18cc dish Speedpro forged pistons on heavy stock rods. I told him to please check first, if anything, weight should need removed from the counter weights. He was going to check, I left Wayne my number🤔.

Yeah, the original balance shop can't do it, it needs weight added. It is going to Percise Engine Rebuilders for internal balancing.

I talked to the machine shop. The balancing shop that only uses lead forgot to send my crank to Precise Engine. Supposedly got dropped off this afternoon. At least I will be able to pick it up in person. I will be in Saskatoon for the next 3 to 6 months, so no rush on this anyways. As long I get it together for spring.

Just got a call from Jim at Precise Engine in Saskatoon. He called me, noticed the really nice parts for my Olds 350, thanks Mark and assumed I wanting it internally balanced, which I do. I mentioned Mark was thinking 2 slugs, he will let me know if it is anything ridiculous. Sounds like the final piece will finally be ready!

Well, anyone who says internal balancing is cheap. It was supposedly balanced with Speedpro forged pistons, it must have been externally balanced or it was another lie. It is on the machine and needs a lot of weight. It is looking at $1500 to internally balance. Oh well it is only money🤑.

JAMCAR223

Member

Christian, I don't get it. That seems like waaayyy too much. Can you elaborate on the reason for the $1500 charge? How many slugs of mallory are required, and how many labor hours are they charging for?

This is blowing your "budget Build" out of the water.

This is blowing your "budget Build" out of the water.

Do I say budget, that is not this build😳. It is 5 slugs of Mallory that it needs. Pretty sure they will be 1.5 times what you guys pay for labour and metal.

Similar threads

- Replies

- 1

- Views

- 3K

- Replies

- 0

- Views

- 3K

Latest posts

-

-

SBO serpentine kit adapter plates With mechanical fuel pump

- Latest: Olds 307 and 403